Test Equipment

-

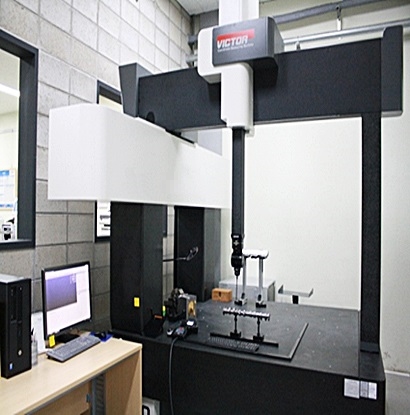

33-Dimensional Measuring M/C

- Measures positions, angles, shapes

- Advanced Surface Extension

- IBM Workstation

-

Universal Measuring M/C

- Tensile test, compression test, bending test

-

Edcole Measuring M/C

- easures cam phase angle, coaxiality, shape tolerance

-

Roundness Measuring M/C

- Measures roundness

-

Gear Profile Measuring M/C

- Measures gear profile and shape tolerances

-

Non-contact Measuring M/C

- Measures cam profile, length, diameter, angle, pitch, etc.

-

Scanning Electron Microscope

- Analyzes microstructure, fracture, chemical composition

-

Metallurgical Microscope

- Analyzes microstructure

-

Stereoscopic Microscope

- Analyzes product conditions

-

Spectrum Analyzer

- Analyzes chemical composition

-

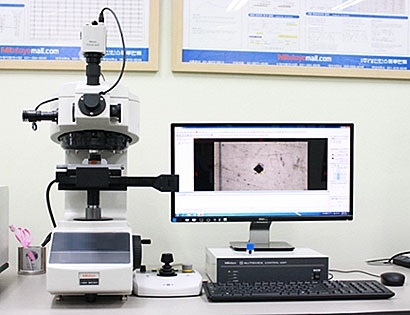

Micro Vickers Hardness Measuring M/C

- Measures micro hardness, effetive case depth

-

Rockwell Hardness Measuring M/C

- Rockwell hardness measurement

-

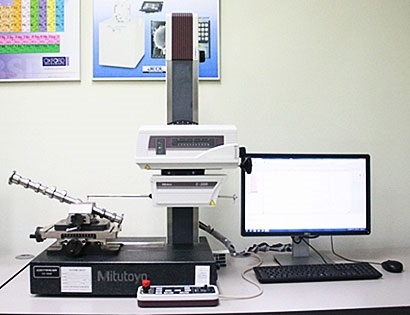

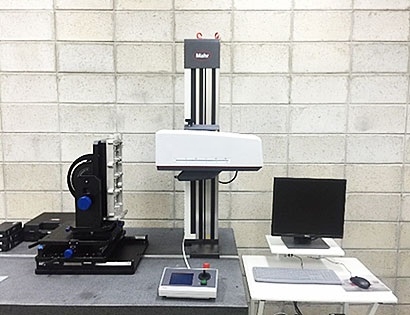

Shape Measuring M/C

- Measures surface shape

-

Surface Roughness Measuring M/C

- Measures surface roughness

-

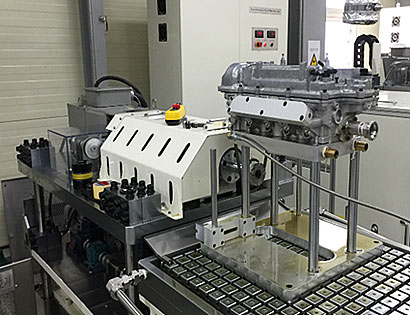

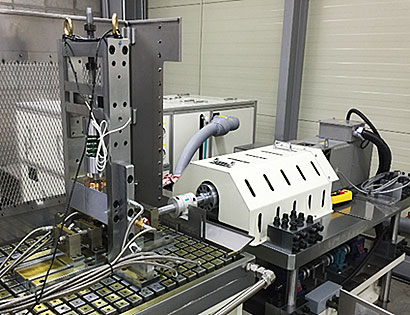

Motoring Testing M/C

- Evaluates camshaft durability

-

Rig Testing M/C

- Evaluates camlobe durability

-

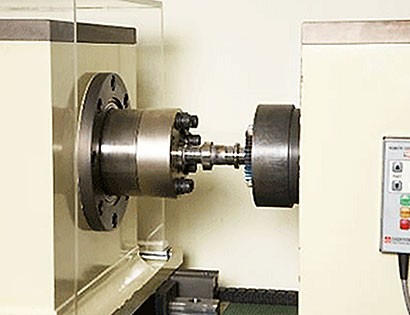

Dynamic Torsional Testing M/C

- Evaluates torsional fatigue properties

-

Static Torsional Testing M/C

- Evaluates rotational torque resistance strength

-

Universal Testing M/C

- Evaluates mechanical strength

-

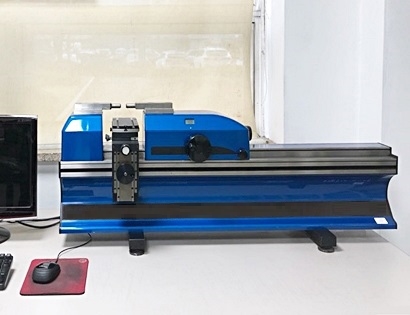

Shape/Roughness Measuring M/C

- Measures product shape and roughness

-

Residual Stress Measuring M/C

- Measures residual stress and retained austenite in cam lobe material